John Deere 3025E

Compact Utility Tractor

- Standard four-wheel drive (4WD) for maximum traction

- Tightest turning radius in its horsepower class

- Hydro transmission with Twin Touch™ pedals for ease of use

Features

3E Tractor engine

3E Tractor engine

3025E

The 1.642-L (100.2 cu in.) displacement, liquid-cooled 3TNV88F-EPJT1 Yanmar® diesel engine provides 18. kW (24.4 hp) to the 3025E.

Model |

Number of |

Engine |

Rated rpm |

Gross engine hp* |

Gross engine ps* |

PTO hp |

3025E |

3 |

1.642 L (100.2 cu in.) |

2400 |

18.2 kW (24.4 hp) |

24.7 |

13 kW (17.4 hp) |

*Engine kW (hp), gross SAE J1995: 18.2 (24.4) at 2400 rpm, PS

Displacement, L (cu in.): 1.642 (100.2)

3032E

The 1.642-L (100.2 cu in.) displacement, liquid-cooled 3TNV88C-NJT Yanmar diesel engine provides 22.9 kW (30.7 hp) to the 3032E.

Model |

Number of |

Engine |

Rated rpm |

Gross engine hp* |

Gross engine ps* |

PTO hp |

3032E |

3 |

1.642 L (100.2 cu in.) |

2500 |

22.9 kW (30.7 hp) |

31.2 |

18.6 kW (25 hp) |

*Engine kW (hp), gross SAE J1995: 22.9 (30.7) at 2500 rpm, PS

Displacement, L (cu in): 1.642 (100.2)

3038E

The 1.568-L (95.68 cu in.) displacement, turbocharged, liquid-cooled 3TNV86T-NJT Yanmar diesel engine provides 27.4 kW (36.7 hp) to the 3038E.

Model |

Number of |

Engine |

Rated rpm |

Gross engine hp* |

Gross engine ps* |

PTO hp |

3038E |

3 |

1.568 L (95.68 cu in.) |

2500 |

27.4 kW (36.7 hp) |

37.2 |

22.4 kW (30 hp) |

*Engine kW (hp), gross SAE J1995: 27.4 (36.7) at 2500 rpm, PS

Displacement, L (cu in.): 1.568 (95.68)

The engine uses the latest technologies to optimize fuel economy, improve control and accuracy, and reduce environmental impact. The common rail system (CRS) optimizes fuel economy and reduces operating costs comparted to engines not using CRS technology. High-pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and a lower cost of operation.

The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions.

The engine comes with an after-treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed, or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC).

After many hours of use, the exhaust filter may require an ash removal service.

DPF cleaning

Depending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three factors:

- A prescribed time-based estimation of needed filter cleaning

- DOC/DPF pressure sensors

- A particulate matter buildup estimation based on load conditions

Once one of the three conditions has been met, filter cleaning will occur.

There are three different types of filter cleaning processes:

- Passive filter cleaning

- Active filter cleaning

- Parked filter cleaning

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Active filter cleaning

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner.

To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize the PM.

It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF.

Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Parked filter cleaning

In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. In general, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process.

The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See the operator's manual for more details.

This system constantly monitors the soot level of the tractor; making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage are viewable on LCD display.

Key features of the engine are:

- Economical cast-in-block cylinder design for good cooling and long life

- Direct fuel injection

- Improves starting

- Injects fuel directly on top of pistons for more efficient combustion

- Develops more horsepower per liter (gallon) of fuel than indirect injection engines

- Aluminum alloy pistons are lightweight to reduce connecting rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, which reduces blow-by and noise from piston slap

- Top rings are higher on the piston and a thinner head gasket is used to greatly reduce the volume of unburned waste gases and increase combustion efficiency

- Timing gears and injector drive gears have a helical profile to reduce engine noise

- Auto-bleed fuel system

- There is no need to prime the system if the tractor runs out of fuel

- The system will self-prime the injection pump, lines, and injectors, providing fast fuel recovery for easier starting

- High-capacity lubrication system provides filtered oil, under pressure, to all engine bearings for long life

- Key start and shutoff eliminate fuel shutoff knob

- Electric solenoid shuts the fuel supply off immediately when key is turned off, which replaces the need to pull a fuel shutoff lever like many older tractors

- Fuel filter with replaceable element

- Water separator with additional replaceable filter element

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

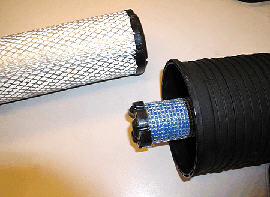

Dry-type air cleaner

Dry-type air cleaner

- Dry-type air cleaner with safety element

- Dual element design for added engine protection

- Easy to service

- Hood can be easily opened without tools for full access to the engine

- Easy access to engine check and fill points on the right-hand side of the tractor by removing the side panels.

Yanmar is a trademark of Yanmar Company Limited.

The 3E Tractors are available with a two-range hydrostatic transmission (HST) incorporated in a die-cast aluminum transmission case. Fluid under pressure transmits engine power to the drive wheels via a closed-loop pump and motor arrangement. Infinite ground speeds allow the operator to match the speed of the tractor to the job.

- No clutching for fast and easy direction changes

- Twin Touch™ foot pedals for quick and easy forward/reverse operation

- Transmission oil cooler cools transmission oil for longer transmission life

Safety features of the HST include:

-

The tractor will only start with the range lever in neutral

-

The engine will shut off if the operator leaves the seat unless the range lever is in neutral

-

The engine will shut off if the operator leaves the seat and the power take-off (PTO) is engaged

Twin Touch foot controls

Twin Touch foot controls

Twin Touch foot controls

Key John Deere advantage - John Deere's Twin Touch foot controls offer several key advantages over competitive HST models tractors.

-

Some competitive hydrostatic tractors use a treadle pedal (toe-heel) design foot control for operation of the HST

- Requires the operator to use both toe and heel to change direction, resulting in increased operator fatigue

- The Twin Touch configuration also makes it easier to "inch" the tractor forward or rearward (i.e., when attaching to implements)

Optional cruise control

Optional cruise control

Optional cruise control

The 3E Series Tractors can be outfitted with an optional cruise control switch that is installed on the right-hand control console. This gives operators the ability to keep a constant speed when in transportation, field mowing, or other applications where extended use of the transmission is needed. This kit is very quick and easy to install for those who desire this feature.

Integrated hydrostatic pump and motor

- Sauer-Danfoss® company provides the integrated pump and motor; this assures that the components are matched to each other, providing maximum efficiency

- Reduces powertrain shock loads

- Provides strength and durability needed for operating such attachments as loaders

- One reservoir (with one check point and fill point) for the transmission, differential, and hydraulic system speeds up daily maintenance

- Mechanically actuated by Twin Touch foot pedals allow selecting both directions of travel and speed with the touch of a toe

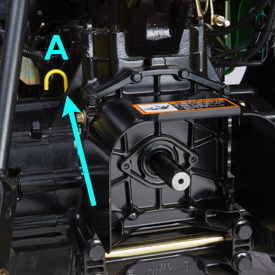

Transmission reservoir fluid checkpoint

Transmission reservoir fluid checkpoint (A)

Transmission reservoir fluid checkpoint (A)

- Easy-to-reach transmission fluid dipstick allows for frequent checks of the transmission fluid level.

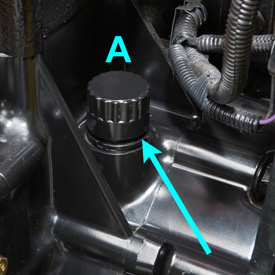

Transmission fill point

Transmission fill point

Transmission fill point

- Easy-to-reach transmission fill point (A) is located on top of rear axles on the right-hand side.

Integrated brake and differential lock pedal

Integrated brake and differential lock pedal

Integrated brake and differential lock pedal

- Foot-actuated differential lock is integrated into the brake pedal to simplify operator controls; the differential lock is included as base equipment to assist traction in tough spots.

- Press the brake pedal down half way to engage the differential lock that locks the rear axle for improved traction in tough spots.

Sauer-Danfoss is a trademark of Sauer-Danfoss Incorporated.

![Clean and simple operator's station (shown with optional selective control valve [SCV] levers)](https://salesmanual.deere.com/sales/salesmanual/images/NA/tractors/cuts/3_series/r4d098800_operator_station.jpg) Clean and simple operator's station (shown with optional selective control valve [SCV] levers)

Clean and simple operator's station (shown with optional selective control valve [SCV] levers)

An uncluttered design gives operators of all sizes plenty of room to be comfortable. Color-coded controls are located on either side of the operator.

- The hydrostatic transmission (HST) and brake pedals are designed and located for maximum comfort and ease of use.

-

Contoured, comfortable seat enhances operator comfort.

- Seat position adjusts fore and aft.

- Seat flips forward for protection from the elements.

- Flat operator platform provides for easy entry to and exit from the tractor.

-

Folding Roll-Gard™ rollover protective structure (ROPS) and retractable seat belt increase operator safety.

Operator presence system:

-

If the operator leaves the seat when the tractor is in gear, the engine shuts down

-

If the operator leaves the seat when the power take-off (PTO) is engaged, the engine shuts down

Left-side step

Left-side step for easy entry/exit

Left-side step for easy entry/exit

-

The left-side step allows for easy access on and off the tractor.

-

Foot platform has a non-skid surface for sure footing.

Seat

Thick, padded seat

Thick, padded seat

The thick, soft padding on this seat provides a smooth and comfortable ride.

- Seat flips forward for protection from the elements.

- Adjustable using the fore and aft lever located under the seat, the seat slides on ramped rails to provide comfortable access to all controls.

Instrumentation

Instrument panel

Instrument panel

Easy-to-read instrument panel includes the following:

- Tachometer

- Low oil pressure indicator light

- Battery discharge indicator light

- PTO engagement indicator light

- Signal/hazard lamp indicator lights

- Multifunction liquid crystal display (LCD) display (hours, filter cleaning information, etc.)

- Filter cleaning status indicator light

Fuel gauge

Fuel gauge

Fuel gauge

All 3E Series Tractors come standard with a fuel gauge that is easy to read from the operator's station to ensure operators do not run out of fuel.

Safety

Operator presence switch (OPS) in seat:

-

OPS requires the operator to be in the seat to operate the transmission or PTO.

-

ROPS is designed to meet or exceed American Society of Agricultural and Biological Engineers (ASABE) safety standards.

-

Reflective ROPS strips for better tractor visibility.

-

Seat belts are in base equipment on all John Deere compact utility tractors.

-

Key switch interlock prevents bypass starting.

-

Visual PTO warning light on the instrument panel alerts the operator when the PTO is running.

-

Turn signal and flashing warning lights operate according to ASABE standards.

-

Slow-moving vehicle (SMV) sign is provided for road transport.

Park brake

Park brake

Park brake

-

Automotive hand-style park brake for easy on/off.

-

Instrument panel has an indicator light for the park brake.

Two-post Roll-Gard ROPS

Roll-Gard ROPS

Roll-Gard ROPS

3E Series Tractors are equipped with Roll-Gard ROPS. These folding ROPS meet the ASABE standards for compact utility tractors.

- With the Roll-Gard ROPS folded down, producers can easily to get their tractor into a garage with a standard 2.1-m (7-ft) garage door.

NOTE: The use of seat belts is recommended at all times when operating the 3E Series Tractor with the folding ROPS upright.

An optional canopy (LVB25334) is available to help protect the operator from the elements.

Rear hydraulic remote kit

Rear hydraulic remote kit

3E Series Tractors can be equipped with a field-installed rear hydraulic remote kit, providing two additional hydraulic spools on the back of the tractor. This kit can be field installed on a tractor with a loader or without a loader.

NOTE: Not compatible with the power beyond kit.

The functions are completely separate from the loader. These rear remotes can be hooked up to a wide variety of implements and attachments such as follows:

- Hydraulically angled blade

- Hydraulically controlled chute/spout on a 3-point hitch-mounted snow blower

- Hydraulic scarifiers on a box blade

- Many other hydraulic rear attachments

This versatile kit gives 3E Series Tractor operators the options they desire for putting their tractors into a wide range of tasks.

The first spool is equipped with a float position, giving the operator the ability to contour the landscape and improve the final grade with certain implements.

NOTE: Neither of the spools in this kit are equipped with a detent position; therefore, they should not be hooked up to anything with a motor, as the valve was not designed to be run open. The kit is designed for momentary, on-demand hydraulic flow such as moving a cylinder.

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the American Society of Agricultural and Biological Engineers (ASABE) Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: The bushing set can be seen in the picture above. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 1.93-1.95 cm (0.76-0.77 in.)

- Outside diameter: 3.15-3.18 cm (1.24-1.25 in.)

- Lower bushings

- Inside diameter: 2.24-2.26 cm (0.88 to 0.89 in.)

- Outside diameter: 3.63-3.66 cm (1.43 to 1.44 in.)

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

- Easy access to most regular service points minimizes service time.

- Four quarter turn fasteners allow operators to easily remove the engine side panels without tools to access the engine compartment.

Quarter turn fastener to remove engine side panels

Quarter turn fastener to remove engine side panels

- Tractors are equipped with extensive onboard self-diagnostic capabilities and are fully compatible with the John Deere exclusive Service ADVISOR™ system.

- Hydraulic oil service interval increased to 1200 hours when using Hy-Gard™ products.

- Hydraulic oil filter will need to be changed every 400 hours.

- Fuel tank is located on the rear of the tractor to allow for easy access when fueling.

Fuel tank at rear of tractor

Fuel tank at rear of tractor

- Gas-lift hood support eliminates the need for a mechanical prop rod.

Gas-lift hood requires no prop rod to service engine

Gas-lift hood requires no prop rod to service engine

- Daily service requirements are minimal and simple to accomplish. Most service interval requirements can be performed with a basic understanding of procedures and common tools.

Removable side panels (previous model shown)

Removable side panels (previous model shown)

All items in the daily service schedule can be performed without the use of tools:

- Engine oil, hydraulic oil, coolant level, and the water separator can be conveniently accessed.

- The engine can be easily accessed by simply raising the hood for more periodic maintenance checks.

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

Specs & Compare

Key Specs | 3025E Current Model |

| Engine power (gross) | SAE J1995 rated power: 18.2 kW 24.4 hp 24.7 PS at 2400 rpm |

| Power take-off (PTO) power | 13 kW 17.4 hp |

| Steering hydraulics | 15 L/min 4 gpm |

| Implement hydraulics | 20.2 L/min 5.3 gpm |

| Hitch type | Category 1 |

| Lift capacity, 24-in. behind link arms | 615 kg 1356 lb |

| Standard transmission; forward/reverse | Hydrostatic transmission (HST) |

| Cruise control | Optional |

| Approximate shipping weight (open-station; cab) | Open operator station (OOS): 1181 kg 2603 lb Cab: Not applicable |

| Wheelbase | 1593 mm 62.7 in. |

Engine | |

| Family | EYDXL1.64NDA FYDXL1.64NDA GYDXL1.64NDA |

| Manufacturer | Yanmar |

| Engine model | 3TNV88F-EPJT2 |

| Engine power (gross) | SAE J1995 rated power: 18.2 kW 24.4 hp 24.7 PS at 2400 rpm |

| Power take-off (PTO) power | 13 kW 17.4 hp |

| Rated engine speed | 2400 rpm |

| Type | Diesel |

| Injection pump type | Direct injection |

| Aspiration | Natural |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | 3 / 1.64 L 3 / 100.2 cu in. |

| Number of cylinders | Three |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 88 x 90 mm 3.46 x 3.54 in. |

| Compression ratio | 19.1:1 |

| Lubrication | Pressurized |

| Cooling system | Water pump |

| Air cleaner | Dual element |

| Engine torque at rated speed | 72.4 Nm 53.4 lb-ft |

| Fuel tank capacity | 28.5 L 7.5 U.S. gal. |

Electrical | |

| Battery size | 500 CCA |

| Alternator (12-V) | 55 amp |

| Starter size | 1.4 kW 1.9 hp |

Fuel system | |

| Type | Direct injection |

| Fuel consumption | |

Transmission | |

| Standard transmission; forward/reverse | Hydrostatic transmission (HST) |

| Optional transmission; forward/reverse | |

| Left-hand reverser | No |

| Transmission gear ranges | |

| Final drive | Spur gear |

| Brakes | Wet disk |

| Steering | Power steering |

| Clutch, wet/dry | |

| Clutch disk diameter wet clutch | |

| Axle capacity | Front 880 kg 1940 lb Rear 1200 kg 2645 lb |

| Creeper | No |

| Cruise control | Optional |

| Differential lock | Yes |

| Drawbar maximum vertical load | |

Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 15 L/min 4 gpm Implement 20.2 L/min 5.3 gpm 35.2 L/min 9.3 gpm |

| Pump type | Dual gear |

| Maximum operating pressure | 172 bar 2495 psi |

| Draft control sensing | Position control |

| Remote control valves available | Up to two (optional) |

3-point hitch | |

| Type | Category 1 |

| Lift capacity, 24-in. behind link arms | 615 kg 1356 lb |

Power take-off (PTO) | |

| Standard | Rear - 540 rpm |

| Optional | |

| Control | Independent |

| Clutch | Wet disk |

| Brake (for mid and rear PTO) | Wet disk |

| Engagement method | |

Fluid capacities | |

| Crankcase with filter | 4.5 L 4.8 qt |

| Transmission and hydraulic system | 20.8 L 22 qt |

Final drive | |

| Type | Spur gear |

| Differential lock | |

Operator station | |

| Rollover protective structure | Type Foldable |

| Platform - flat/straddle | Straddle |

| Gear shift location - console/floor | Left-hand side |

Cab | |

| Compliance | |

| Visibility | |

| Air conditioning, temperature differential | |

| Doors | |

| Noise rating | |

| Seat equipment | |

Dimensions | |

| Height | |

| Wheelbase | 1593 mm 62.7 in. |

| Front axle clearance | Minimum: 299 mm 11.8 in. Maximum: 333 mm 13.1 in. |

| Turning radius with brakes | |

| Turning radius without brakes | 2.9 m 9.4 ft |

| Limited slip differential | |

| Approximate shipping weight (open-station; cab) | OOS: 1181 kg 2603 lb Cab: Not applicable |

Tires | |

| Front | R1 Bar: 7-14 R3 Turf: 27x8.5-15 R4 Industrial: 25x8.5-14 R4 Industrial: 27x8.5-15 |

| Rear | R1 Bar: 11.2-24 R3 Turf: 41x14-20 R4 Industrial: 15-19.5 R4 Industrial: 43x16-20 |

| Front tread range | |

| Rear tread spacing | |

Miscellaneous | |

| Toolbox | |

| Tilt steering wheel | |

| 12-V Outlet | |

Additional information | |

| Date collected |

Offers & Discounts

Reviews

Location: TX

Length of Ownership: 3months

Usage: Weekly

Purchased and finally took delivery in July 2022 after waiting six weeks for the Mechanical Self-Leveling loader to come in. The 3025E seems to be underpowered and the loader with it's lack of "full curl" like the Non-Self Leveling variant is a disappointment. Was hoping for more. However, with no MSL loaders available on dealers' lots and lack of sales knowledge, it's a shot in the dark and unfortunately isn't shared by Deere anywhere on their website or in their videos. About the only plus on this loader when using pallet forks, it keeps your load level. But using the bucket and attempting to scoop a full load of material, it's not achievable. My dealership has attempted to help but claims there is nothing wrong with the product.

Location: Pallmall tn

Length of Ownership: 1yearOrLonger

Usage: Daily

I have owned a 3025e for a year now. This little tractor has been great. For a small tractor it will do some big jobs. Pallet forks are a must have for this tractor. When they say it will pickup 1,200 pounds it will and then some. Hands down one of the best purchases of my life.

Location: Tracy City, TN

Length of Ownership: 1week

Usage: Weekly

I recently purchased my Deere 3025E from TriGreen in Winchester, TN outfitted with the Brush Crusher 4200, & Frontier box blade, & liquid ballast in the rear tires. This thing is a beast! I've moved several 8ft-12ft oak & pine logs with an average diameter of approx. 22 inches with ease...I mean, the thing doesn't grunt or show signs of stress at all with those logs. Pulled up a stump that I've been trying to dig out with a shovel, & this thing popped it out of the ground like a rag doll. This thing has a slimmer profile, & the turning radius is amazing so I can really work my way through the woods with ease. I can maneuver this thing into tighter places than my Honda Rancher ATV if you can understand what I mean. Yes, the ATV is smaller, but the tractor can be gently maneuvered in and out of spots that look impossible. If you are dealing with logs, wood, brush etc. you will DEFINITELY appreciate the plastic fenders and hood. It's the same type of quality plastic you'll find on any ATV body. There is a reason they use plastic on these machines that are running and working in the woods. I received the tractor, lift bucket, grapple, & box blade for a better price than any other brand of tractor out there, & I test drove them all. It's a John Deere-holds it value better than any other brand in the market, & the parts/dealer network is the best in the US obviously. The decision was easy for me, & I'm glad I added this tractor to our family.

Location: Oregon

Length of Ownership: 6months

Usage: Daily

Got 8 acres. Does everything i need well. Brush Hog, bucket, and loader work well. Handles full bucket of gravel or dirt well. Mower cuts nice too. Runs like a top

Location: South texas

Length of Ownership: 1yearOrLonger

Usage: Weekly

It is a little light for brush hogging high grass. But you have to understand, get the right tractor for what it's designed for. You don't brush hog 18" of grass with a 24hp tractor. It was not designed for that. You will bog down the engine just like anything else that gets overloaded. If you are doing a lot of brush hogging in high grass, get a 65hp 4 series with a flexwing mower. But overall, it does just about everything that I need. The lift capacity of the front end loader is pretty good but you have to be careful. You can easily overload it. If you need to do heavy lifting, get the right tractor for your needs. But for what I use it for, it's a great little tractor. I have a 60" finish mower that I use on 3.5 acres. The finish mower does an excellent job. As with any mower, make sure the blades are sharp. Don't sell this tractor short. It has a lot of potential and capabilities. But do your homework first and make sure it's right for what you are going to use it for. I see so many posted CON's where an item is being used beyond it's capabilities. If your using this tractor or any tractor for what it was not designed for, don't post CON's. Only post CON's if it does not perform to it's capabilities.

Location: Burkburnett, TX

Length of Ownership: 1month

Usage: Daily

We have been needing a tractor with a brush mower, kept looking around for several years now. Did some research and as far as value and warranty for the money, this was the tractor to get. Came with the front loader, added a 5ft rotary (brush) mower and the wife and I are extremely happy with this purchase. We've only had the tractor for a few weeks now, but have gotten so much more done on our property in those few weeks that would have taken much much longer without it. Have projects lined up to do ourselves now that we have it. Even got my youngest daughter using it as well.

Pros:

- size

- hydrostatic transmission

- front loader

- 4wd

- warranty support

- dealer support

- ability

Cons:

- none

Location:

Length of Ownership: 1yearOrLonger

Usage: Weekly

We have larger tractors for the farm but I needed something smaller to haul around and use in residential yards. The 3025 is perfect size. It’s big enough to do stuff but small enough to tow with a half ton p/up. Take care of it and it will hold its value better than any other brand. Get 32 inch pallet forks and add two more forks for brush and save your money on a grapple. It’s amazing what All you can do with this setup and this tractor.

Pros:

- no emission junk

- foldable rops

- resale value

- perfect size

Cons:

- hydrostat not as good as gear for field work

Location: North florida

Length of Ownership: 1yearOrLonger

Usage: Monthly

I have had this tractor for 2.5 years (2017 model) I have put on nearly 200 hours. It has been 100% reliable and is perfect for what I need it for. I have a 5 ft rotary cutter and a box blade. Between these and the bucket you can get a lot of work done. Simple to operate and gets the job done.

Location: Anderson, MO

Length of Ownership: 1yearOrLonger

Usage: Daily

I purchased my 3025E in May, 2017. I have owned it for 2.5 years now and it has been absolutely reliable. Not a single trip back to the dealership, and no on site service calls. I use my tractor almost on a daily basis. As of today it has 536.1 hours on it. I got the loader, 60 rotory cutter, 60" box scrap, and a used 48 King Kutter BX roto tiller. I have seen complaints about lack of PTO HP, but that hasn't been my experience with my tractor. I also picked up a used Woods RM59 finish mower, no issues running that either. This is my first tractor, and after doing much research and visiting other dealerships before my purchase, I'm very happy that I went with JD.

Pros:

- extremely capable machine.

- very fuel efficient.

Location: Texas

Length of Ownership: 6months

Usage: Monthly

Ive had my 3025 for about 6 months now. My field is about 6 acres. If you are going to use this to shred (I have the 60" frontier cutter that came with the pkg) I would definitely recommend gettting the 3032 or 3037. The 25 hp from the 3025 with about 17 hp to the pto just dont cut it. No pun intended. Seriously, the tractor bogs down bad. You have to go very slow, foot barely on the pedal, or the pto rpm drops way down. Or even stop moving forward for a few seconds to let it speed back up. Grass height was about 18" first cutting but only about 10" second cutting. I was going to get a 3032 or 3037 but a guy at work told me all new tractors over 25 up now had the exhaust requirement of recycling or soot burning (or whatever) cycle and the exhaust systems were always getting plugged. I talked to john deere and they said the cycle goes well with no exhaust system problems as long as you used low sulfur diesel, which is what you get at the gas station. But they also told me the 3025 would handle that field with no problems. Untrue. It takes me 10-12 hours to mow 6 acres when other tractors have mowed it in 2 or 3. Spend the extra 2000-3000 dollars and get the 3032 or 3037 . you'll be glad u did.

Pros:

- compact ease of use

Cons:

- low pto power cutter bogs down

Videos